Introduction

Small scale and cottage industries are crucial in developing economies, and their role is even greater in the largely rural economies of South Asia. In India, the sector is the second largest employer, after agriculture, and accounts for nearly 6 percent of the country’s GDP. Cottage industry or home industry means the manufacturing of goods at home by hands, with small capital and on a small scale by the members of a family. Cottage industries are part time or supplementary occupations. In the past, cottage industries played an important role in the economy of our country. They provided employment to a large number of people. The destruction of the cottage industries is one of the main causes of poverty in our country.

Ours is an age of machine and large scale industries. Yet even in the highly industrialized country like Japan and Germany, a good proportion of their industries are run in a ‘domestic’ system. In India cottage industries have a more important part to play than any other country. They can help a lot in solving the problem of unemployment and poverty. For more than four months in a year, our cultivators have no work to do. Cottage industries can give the cultivator useful employment during spare time. That was why Mahatma Gandhi laid emphasis on reviving the dying cottage industries. Since Independence the country, the government too has been making all possible efforts in this direction.

Cottage Industries can successfully complete with machine made goods, if they are run on modern lines. Periodic exhibitions of the good; manufactured by Cottage Industries and development of Co-operative system are of great advantage for their progress. Co-operative system can help in solving the problems of capital, raw material and marketing them, then they would easily withstand the competition of large Scale factory production. Forest products play a crucial role in the context of cottage industries, as they serve as a primary source of raw materials for various products.

Methods

The project followed a multi-step methodology. A literature review on small-scale cottage industries was conducted, followed by field visits and surveys in selected forest regions to understand traditional methods and challenges. Local stakeholders were engaged to gather insights on the need for improved manufacturing techniques.

A prototype of a manually operated machine for Hirda and Bheda cracking and seed extraction was designed, considering ergonomics, cost-effectiveness, and local context. The prototype was tested in the field, refined based on feedback, and its impact on productivity, fatigue reduction, and health outcomes was assessed. Findings and recommendations were documented for future research and implementation in similar contexts.

Results

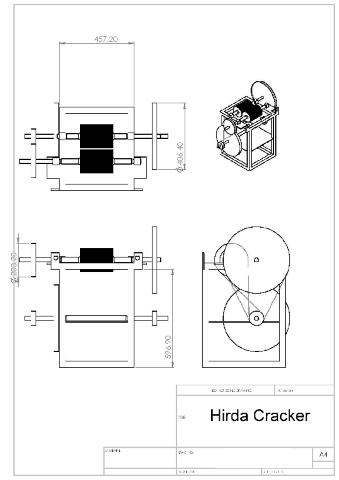

The Hirda cracking machine was developed using a single-phase 1HP induction motor, which provided input power to the system and rotated at a speed of 1440 rpm. Power was transmitted to the common shaft through a V-belt drive and then to the left roller. The right roller, which required rotation in the opposite direction, was powered through a crossed V-belt drive. A hopper was provided over the rollers, where the Hirdas were fed into the system. The Hirdas would get cracked as they passed through the rollers, which rotated in opposite directions. The cracked Hirdas, along with their inner seeds and outer shells, were collected in a tray below the rollers, requiring manual separation.

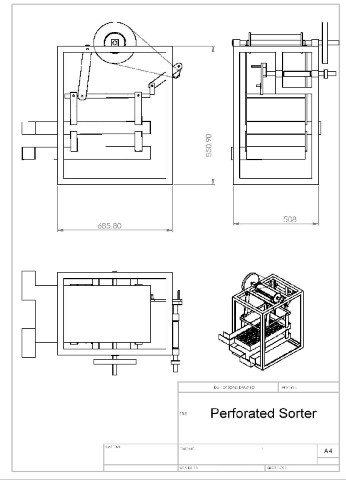

A perforated sorter was also designed to sort the Hirdas based on their size before passing them through the cracking machine. The Hirdas were fed into a sorter shaft, which contained a roller with two slots on its curved surface. As the shaft rotated, the Hirdas fell into the slots and were passed down to trays below. The rotating shaft provided power to oscillate the trays using an eccentric shaft. The Hirdas would then fall into the first perforated tray, which would separate the smaller Hirdas into a lower tray through the oscillation process.

Overall, the Hirda cracking machine and perforated sorter successfully processed and sorted the Hirdas according to their size, streamlining the cracking process and improving efficiency.

Conclusion

In conclusion, this study explored the challenges faced by small-scale cottage industries in rural and forest areas of India and developed an ergonomic, cost-effective, and locally suitable manually operated machine for Hirda and Bheda cracking and seed extraction. Field testing and user feedback led to design refinements, resulting in a practical solution that positively impacted productivity, fatigue reduction, and health outcomes among the tribal workforce.

The study’s findings and recommendations provide a foundation for future research, implementation, and policy development to support cottage industries in similar contexts. By focusing on sustainable and contextually appropriate solutions, it is possible to enhance the livelihoods of tribal communities and foster economic growth while preserving their cultural heritage.